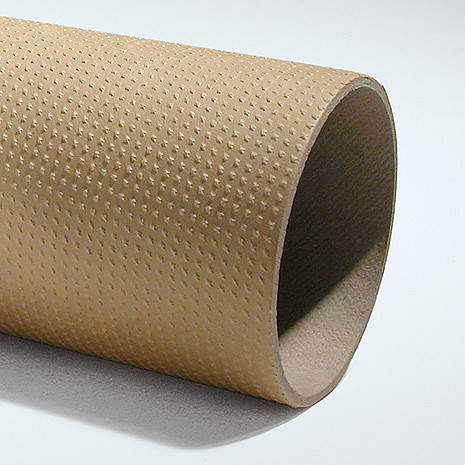

Sensitive products such as textiles and non-wovens place high demands on the winding core. At Beillard Tubes Carton S.A. we have understood this and so together with you we developed paper cores that meet your individual requirements in the textile industry. With our paper cores you can be confident: Your goods reach their destination in good condition.